PRODUCTS

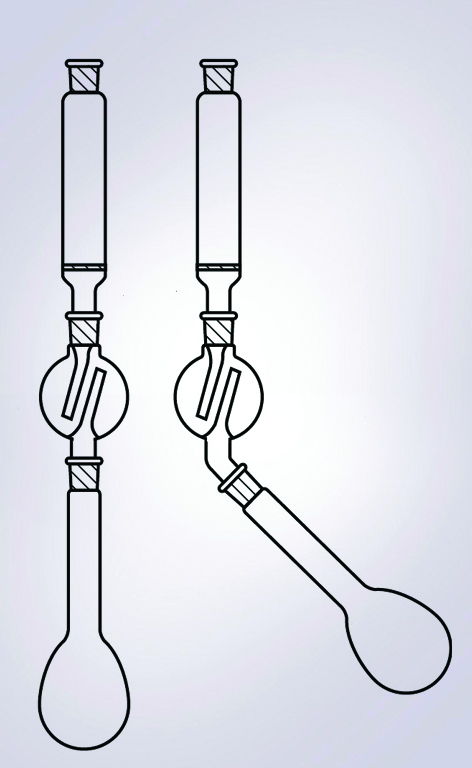

Absorption Traps

Material : Schott Duran Germany & Iwaki Pyrex Japan

Borosilicate glass

These Units enable acid fumes ecountered in kjeldahl digestions to be handled on the open bench without mechanical fume extraction. The traps consist of two chambers. In use, the lower chamber is approximately half filled with 10% caustic sada solution, care being taken that none passes down the inner tube when fitting it to the flask. Fumes which are evolved force this solution into the upper chamber until the level drops below the drip tube in the lower chamber. Fumes then pass up through the sintered disc which assists absorption by fine division of the bubbles.

To promote an efficient long life, the disc must be cleaned and washed regularly after use. Sodium sulphite deposits should be removed with hydrochloric acid. If this is not done, blockage of the sintered disc may cause the apparatus to blow apart, particularly if violent heating is used in of intial stage.

Digestions involving the use the selenium catalysts often result in enterinment of volatilised selenium in the sulphur dioxide, with consequent contamination of the sintered disc. It can be removed from the discs using concentrated sulphuric acid, but wherever possible other catalysts should be used to ensure effective use of the absorption trap.

Any other contamination of the disc, e.g. soduim sulphite or small amounts of material filtered out of the fumes, should be cleaned after each digestion using a suitable reagent.

Absorption traps can also be used for absorption of other noxious acid gases such as hydrogen chloride in Friedel-Crafts reactions.

| Cat. No. | Description | Capacity(ml) | Socket Size | Cone Size |

| CA 12/33 | Lower Chamber – Straight | 250 | 24/29 | 24/29 |

| CA 12/33B | Lower Chamber – angled 45′ | 250 | 24/29 | 24/29 |

| CA 13/33 | Upper Chamber | – | 24/29 | 24/29 |

Others Size On Request

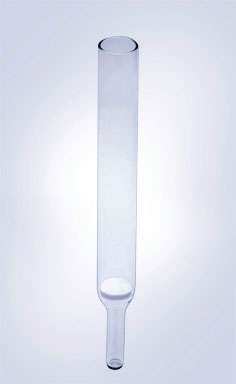

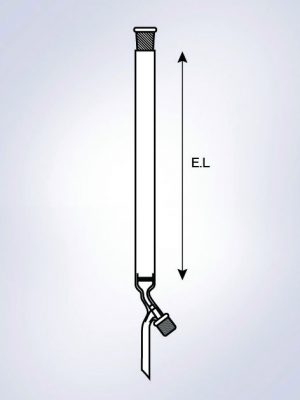

RELATED products

Related products

56-M, Jalan Metro Perdana Timur 11, Kepong Entrepreneur’s Park, 7th Miles,

Kepong Road, 52100 Kuala Lumpur, Malaysia

- +603-6251 7199 / +603-6252 6639 / +603-6242 7719

- +603-6258 4639

- [email protected]

© 2023 DURAGLAS SDN BHD (200101012252 / 548008-V). All Rights Reserved.